High-Quality Non-Rising Stem Gate Valve Manufacturer: Expert Solutions for Industrial Applications

2025-12-30

In the demanding world of industrial applications, selecting the right valve is crucial for efficiency and safety. As a leader in precision engineering, DRIFCO excels as a high-quality non-rising stem gate valve manufacturer, offering expert solutions tailored to complex environments. Our innovative designs ensure reliable performance, minimizing downtime and enhancing operational workflows. At DRIFCO, we combine cutting-edge technology with decades of experience to deliver valves that meet stringent standards. Curious to learn how our products can transform your operations? Explore our comprehensive range and discover why industries trust DRIFCO for durable, high-performance solutions. Stay tuned as we delve into the key features and benefits that set our valves apart.

Essential Features of High-Quality Non-Rising Stem Gate Valves

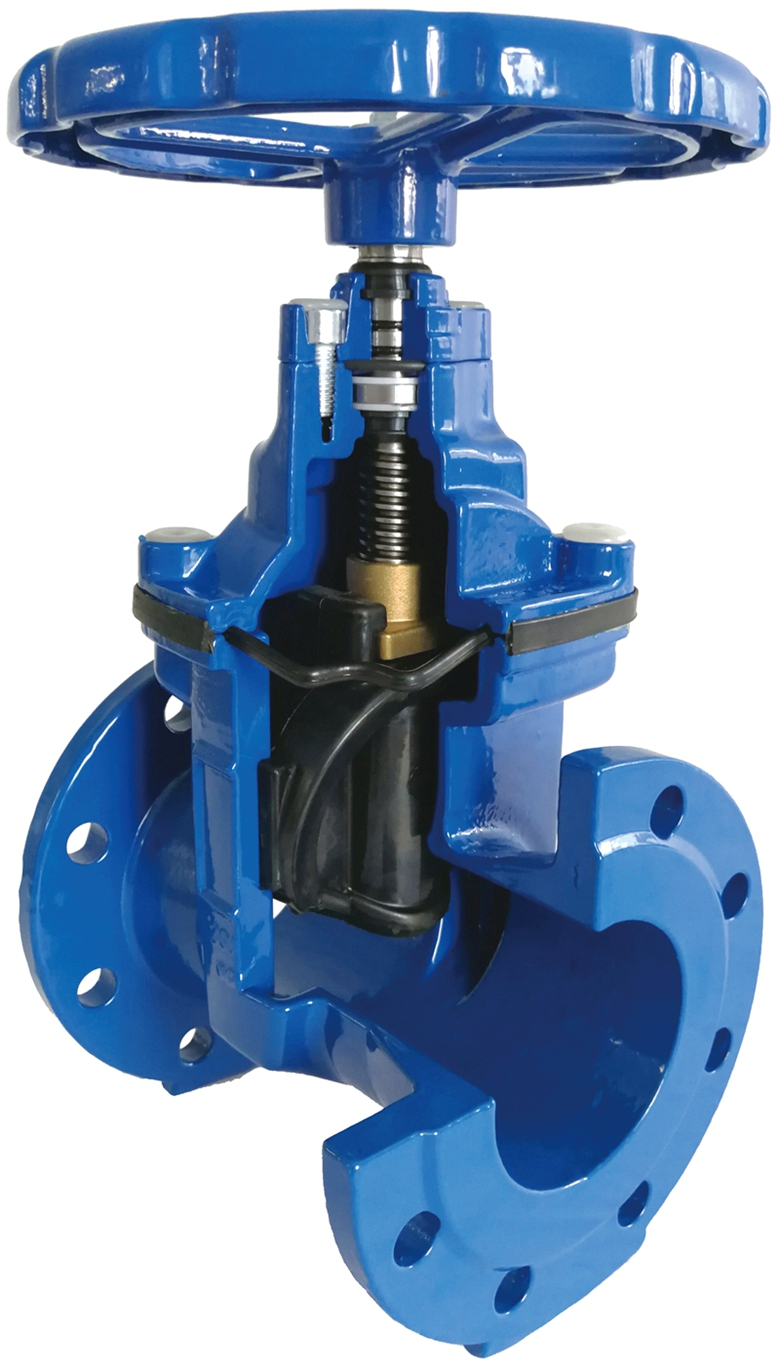

High-quality non-rising stem gate valves excel in applications where space is limited, thanks to their unique design that keeps the stem stationary while the gate moves. This feature ensures smooth operation without the stem rising above the valve body, making them ideal for underground or confined installations. Manufacturers prioritize robust materials like stainless steel or bronze to enhance durability and resist corrosion, ensuring long-term reliability in harsh environments such as water treatment plants or industrial pipelines.

Another standout aspect is the precise sealing mechanism, which minimizes leakage and maintains tight shut-off capabilities. Advanced designs incorporate resilient seats or metal-to-metal seals, adapted to handle varying pressures and temperatures. These valves often feature ergonomic handwheels or actuators for ease of use, reducing operator effort and enhancing safety. By focusing on low maintenance and high performance, they outperform many alternatives in terms of operational efficiency and cost-effectiveness over their lifespan.

Innovations in non-rising stem gate valves include enhanced stem protection systems that prevent external damage and contamination, further boosting their suitability for critical infrastructure. Customizable options, such as specialized coatings or extended warranties, allow users to tailor valves to specific needs, setting them apart from standard models. This attention to detail ensures they meet rigorous industry standards while offering unique benefits like reduced installation time and improved flow control, making them a preferred choice in sectors like oil and gas, where precision and reliability are paramount.

How Non-Rising Stem Design Enhances Industrial Efficiency

In industrial settings where space is at a premium, the non-rising stem design offers a compact solution that minimizes vertical clearance requirements. This design keeps the stem stationary while the valve operates internally, allowing for installation in tight locations like pipelines close to ceilings or in crowded machinery setups. By eliminating the need for extra overhead space, facilities can optimize their layout, reducing the risk of interference with other equipment and enhancing overall workflow efficiency.

Maintenance routines benefit significantly from non-rising stem valves, as their design inherently reduces wear and tear on components. Since the stem does not move up and down during operation, there is less friction and exposure to external contaminants, leading to longer service intervals and fewer unexpected breakdowns. This reliability translates into lower downtime costs and more consistent production output, making these valves a preferred choice in industries like oil and gas or water treatment where operational continuity is crucial.

From an energy perspective, the non-rising stem configuration contributes to improved efficiency by minimizing the force required to actuate the valve. The internal mechanism allows for smoother operation with less torque, which can reduce the load on actuating devices such as motors or manual handles. This not only conserves energy but also extends the lifespan of associated equipment, providing a sustainable advantage that aligns with modern industrial goals of reducing resource consumption and operational expenses.

Innovative Manufacturing Techniques for Durable Valve Solutions

In our relentless quest for reliability, we have pioneered advanced additive manufacturing methods for valves, enabling complex internal geometries that boost flow efficiency and reduce wear. By leveraging 3D printing with high-strength alloys, we craft components that not only meet stringent industry standards but also excel in extreme environments where traditional valves falter. This approach allows for rapid prototyping and customization, ensuring that every valve solution is tailored to specific operational needs, from oil and gas applications to water treatment systems.

Beyond additive techniques, we incorporate precision machining and automated assembly lines to enhance durability and consistency across production batches. Smart sensors and real-time monitoring are integrated during manufacturing, enabling predictive maintenance features that extend valve lifespan and prevent costly downtime. Our focus on sustainability also drives the use of recycled materials and energy-efficient processes, resulting in eco-friendly valve systems that perform reliably over decades without compromising on environmental responsibility.

To stand out in a crowded market, we combine these innovations with rigorous testing protocols, including accelerated life cycles and failure analysis, ensuring that our valves deliver unmatched resilience. By fostering collaboration with engineers and end-users, we continuously refine our techniques, adapting to emerging challenges like corrosion resistance in harsh chemicals or high-pressure demands. This holistic approach not only elevates performance but also sets new benchmarks for durability, making our valve solutions a trusted choice for critical infrastructures worldwide.

Applications and Benefits in Demanding Industrial Settings

In demanding industrial environments such as heavy manufacturing, mining, and power generation, robust equipment is essential for maintaining uninterrupted operations. These settings often involve extreme conditions like high temperatures, corrosive chemicals, and significant mechanical stress. Applications here include automated handling systems that manage raw materials, precision machining tools for creating critical components, and monitoring systems that track equipment health in real-time. Implementing advanced technologies like IoT sensors and predictive maintenance algorithms allows these industries to preemptively address potential failures, reducing costly downtime and enhancing overall productivity.

The benefits of deploying specialized solutions in these harsh settings are multifaceted. Safety improvements are a primary advantage, with automated systems minimizing human exposure to hazardous conditions, thereby lowering accident rates. Efficiency gains are also substantial, as optimized machinery can operate at higher speeds with greater accuracy, leading to increased output and reduced waste. For example, in the oil and gas sector, advanced drilling equipment not only speeds up extraction but also minimizes environmental impact through better control over processes. These benefits translate into significant cost savings and strengthened competitive edges in global markets.

Beyond immediate operational perks, these applications foster long-term sustainability and innovation. By integrating energy-efficient designs and renewable energy sources, industries can cut down on resource consumption and carbon footprints, aligning with global environmental standards. This proactive approach not only meets regulatory demands but also attracts eco-conscious investors and customers. Ultimately, investing in tailored industrial technologies drives continuous improvement, enabling businesses to adapt to evolving challenges and seize new opportunities in a dynamic economic landscape.

Customization Options to Fit Specific Operational Needs

Tailoring our solutions to meet your unique operational needs is at the heart of what we do. Whether you're managing a small startup or a large enterprise, we offer flexible customization options that adapt seamlessly to your workflows. This means you can adjust features, integrate with existing systems, and scale resources as your business evolves, ensuring a perfect fit without unnecessary complexity.

We focus on practical adjustments that enhance efficiency and reduce overhead. Instead of one-size-fits-all approaches, we work closely with you to identify specific challenges—like streamlining inventory management or automating customer support—and craft bespoke tools that address these directly. This results in smoother day-to-day operations and a noticeable boost in productivity, tailored precisely to your team's methods.

Our customization process is designed to be intuitive and collaborative, allowing for ongoing refinements as your needs change. We provide a range of modules and add-ons that you can mix and match, ensuring the solution grows alongside your business. By prioritizing user feedback and real-world application, we deliver not just software, but a dynamic partnership that keeps your operations agile and future-ready.

Expert Tips for Selecting and Maintaining Gate Valves

Choosing the right gate valve starts with assessing the specific media it will handle. For instance, if you're dealing with corrosive fluids like acids or alkalis, opt for valves made from stainless steel or specialized alloys that resist chemical attack. Don't overlook the pressure and temperature ratings—exceeding these can lead to leaks or valve failure, so always check manufacturer specs against your system's operating conditions. Consider the valve's end connections too; flanged gate valves are great for high-pressure applications, while threaded ones suit simpler setups, ensuring a secure fit without extra adapters.

Proper installation is key to maximizing a gate valve's lifespan. Ensure the valve is oriented correctly—usually with the stem upright to prevent sediment buildup—and avoid overtightening during assembly, as this can warp components. Before use, conduct a pressure test to spot any initial leaks; a slow closing and opening during the first few cycles helps seat the disc properly. For maintenance, make it a habit to inspect the valve periodically, especially in harsh environments, and keep a log of any adjustments or replacements to track wear over time.

Routine upkeep goes beyond basic checks—lubricate the stem and packing regularly with a compatible grease to reduce friction and prevent seizing. If you notice persistent issues like sticking or leakage, don't just force it open; disassemble the valve to clean out debris or replace worn parts like gaskets or the gate itself. Storing spare valves in a dry, clean area can save downtime during emergencies. Remember, a well-maintained gate valve not only operates smoothly but also extends the overall system's reliability, making these practices worth the extra effort.

FAQ

Non-rising stem gate valves offer superior reliability in high-pressure environments due to their compact design that reduces external corrosion risks, with maintenance minimized as the stem doesn't extend outside the valve body, enhancing safety and durability.

Our process integrates precision casting and rigorous testing protocols, including pressure and material analyses, to guarantee leak-tight performance and longevity across diverse industrial applications, with custom engineering support available.

Sectors like oil and gas, petrochemicals, and water treatment rely on these valves for pipeline control and isolation tasks, where their robust construction handles demanding conditions effectively.

We utilize materials like stainless steel, carbon steel, and alloys selected for their corrosion resistance and strength, tailored to application requirements to optimize performance and cost-efficiency.

In non-rising stem valves, the stem threads into the gate and rotates without moving vertically, conserving space and reducing wear compared to rising stem designs, which extend outward during operation.

Regular inspection for debris, lubrication of internal components, and adherence to operational pressure limits are recommended, with detailed service plans provided to prevent failures and ensure consistent functionality.

Conclusion

High-quality non-rising stem gate valves are essential components in industrial applications, offering durability and efficiency through their unique design. Key features include corrosion-resistant materials and tight sealing mechanisms, which ensure reliable performance under high-pressure conditions. The non-rising stem design enhances industrial efficiency by minimizing space requirements and reducing maintenance needs, allowing for seamless operation in confined areas. Innovative manufacturing techniques, such as precision machining and advanced alloy casting, contribute to the longevity of these valves, making them suitable for demanding environments like oil refineries and chemical plants. By integrating these elements, manufacturers provide expert solutions that prioritize safety and operational continuity.

The benefits of non-rising stem gate valves extend across various demanding industrial settings, including water treatment facilities and power generation plants, where they help prevent leaks and ensure smooth flow control. Customization options, such as tailored sizes and material selections, enable these valves to fit specific operational needs, enhancing versatility in diverse applications. Expert tips for selection and maintenance emphasize proper installation, regular inspections, and proactive replacement of worn parts, which collectively extend valve lifespan and optimize performance. Overall, this focus on quality and adaptability underscores the critical role of reputable manufacturers in delivering solutions that meet the evolving challenges of modern industry, fostering reliability and cost-effectiveness.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com